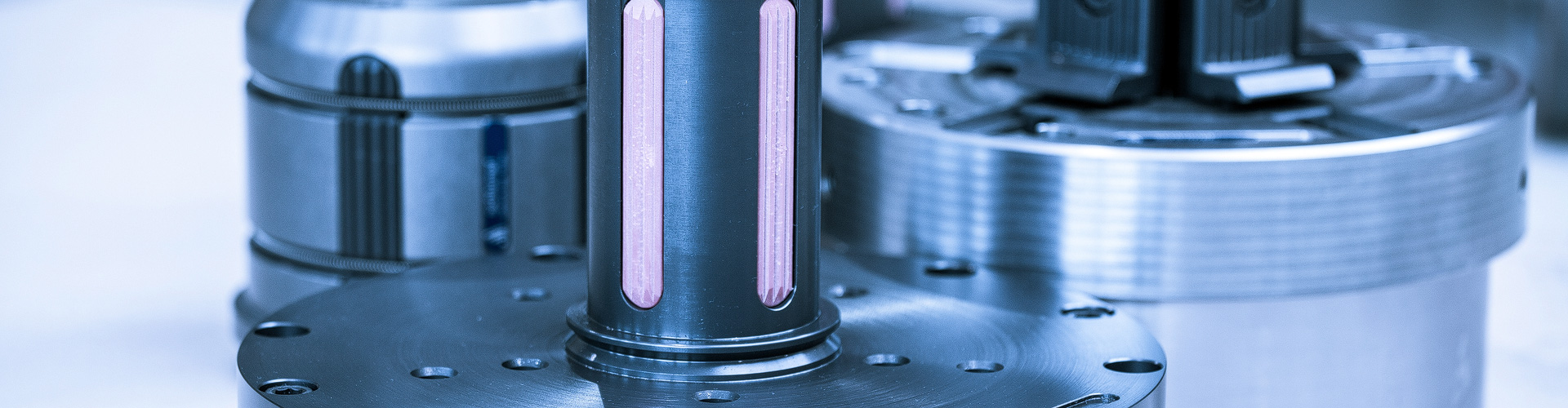

SDE Core Chuck Standard

- Core inner diameter from 70 to 152.4 mm

- Expansion way 11 mm

- Load from 12`500 N/Chuck to 30`000 N/Chuck

- Torque from 300 Nm to 2`580 Nm

- Maximum productivity thanks to minimal changeover and maintenance times

SDE Easy Service Concept

Increase your productivity with minimal maintenance costs

SDE Core Chucks with Easy-Service-Concept

Maintenance in less than 5 minutes WITHOUT removing the Core Chuck!

For

us it’s a matter of course. And for you? The SDE Core Chucks

from the company Schlumpf AG minimize maintenance costs and shorten

maintenance times to a few minutes.

Our SDE Core Chucks for the axle-free up-and-down path-shaped materials guarantee trouble-free operation, meaning your machine is easily and efficiently maintained.

Do not put your highest value asset at risk and secure your ROI with proper investment.

Our

Core Chucks help you to achieve a sustainable competitive advantage,

whether you roll weights up to 9 tons mechanically or pneumatically.

The SDE Core Chucks, which guarantee maximum flexibility due to

their unique adaptation method, are capable of winding core up to 600

mm.

We would be pleased to advise you from the design of your solution to the implementation and execution.

«Anyone can count on investing in intelligently designed components!»

Unique Easy-Service-Concept

Maintenance in less than 5 minutes WITHOUT removing the Core Chuck!Product features

SDE Core Chucks are actuated by compressed air via an integrated piston.

They clamp the core precisely i the center without slipping thanks to

large expansion range. SDE Chucks are also available as SF type with spring force actuation and compressed air relaxation.

.

Thanks to the Easy-Service-Concept, normal cleaning and maintenance work is carried out from the outside without removal of the Core Chuck from the machine.

SDE Core Chucks can be quickly applied to other diameters by means of plug-on adapters between 70 mm an over 300 mm (3"-12") converted. Highest productivity thanks to precise winding of the roler with minimal changeover and maintenance times.

The advantages of SDE:

- Resistant construction

- High torque transmission

- Easy Service Concept

- Proven technology

- Quick changeover times to other core diameters with plug-on adapters